As manufacturers scale their operations across multiple sites, the complexity of quality and compliance management increases significantly. With each additional location, businesses face challenges like inconsistent quality control, data silos, regulatory complexity, and operational inefficiencies.

AuditComply is designed to address these challenges, providing manufacturers with a scalable, integrated platform that unifies Quality Management Systems (QMS) across all sites, ensuring consistent quality, compliance, and operational efficiency.

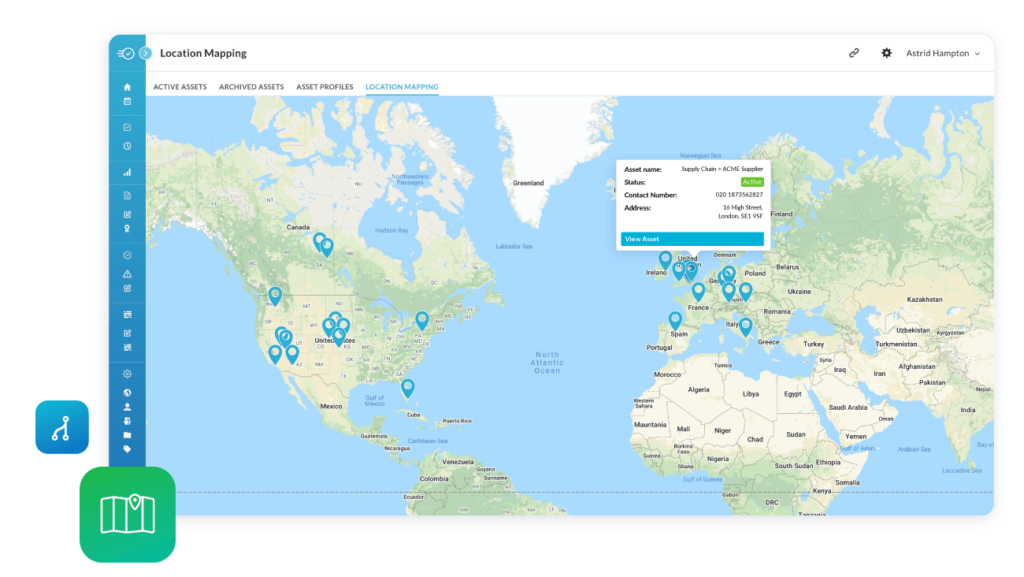

Centralized Visibility Across Multiple Sites

For manufacturers, maintaining visibility across numerous sites is critical. Without a unified system, data becomes fragmented, and decision-making suffers. AuditComply’s centralized platform overcomes this by providing a holistic view of quality and compliance performance across all locations.

Key Features:

- Asset Tree Structure: Organize complex site hierarchies, from individual production lines to entire facilities, with a logical, tree-like structure. This approach ensures accurate data capture and streamlined asset management.

- Real-Time Analytics: Access performance metrics in real-time, enabling faster identification of non-conformances and proactive issue resolution.

- Cross-Site Benchmarking: Compare the performance of different locations, identify outliers, and implement best practices consistently.

Customized, Site-Specific Quality & Compliance Templates

Standardizing quality processes across multiple sites is a significant challenge, particularly when each location must comply with different regional regulations or customer-specific requirements. AuditComply’s customizable templates provide a solution, allowing manufacturers to tailor audit and compliance checklists to each site’s specific needs.

Real-World Impact:

- Reduced Implementation Time: One global manufacturer reduced site rollout time using AuditComply’s template builder, which allows for rapid deployment of tailored compliance frameworks.

- Enhanced Flexibility: Easily adjust templates as regulatory requirements evolve, ensuring ongoing compliance without disrupting operations.

A major food producer using AuditComply saw a reduction in audit preparation time by automating site-specific documentation, improving audit readiness and response times.

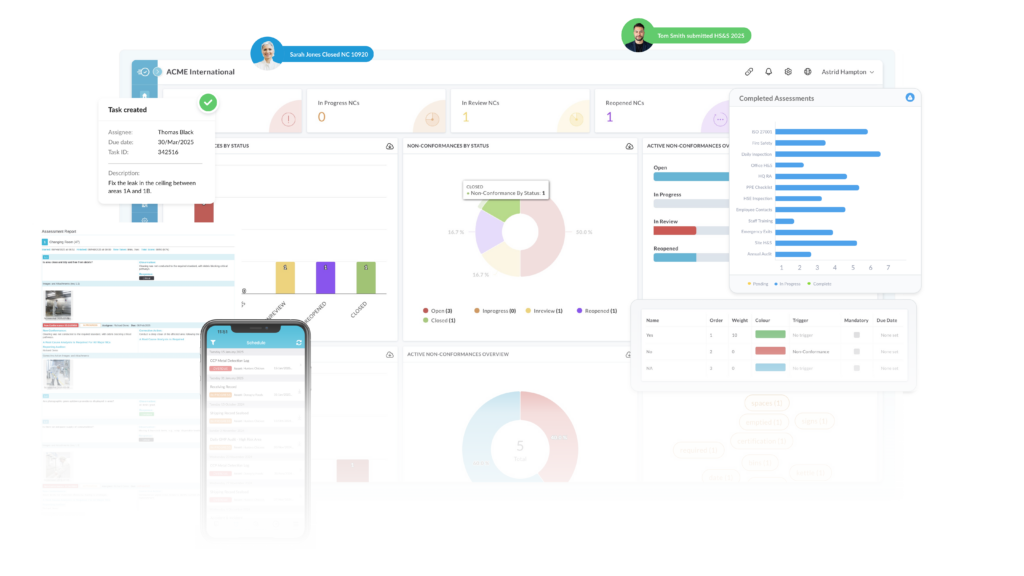

Automated Roll-Up Reporting for Complete Oversight

Managing quality and compliance across numerous sites requires more than just data collection. It demands the ability to quickly generate insights and reports that drive operational decisions. AuditComply’s automated roll-up reporting transforms raw data into actionable intelligence.

Key Benefits:

- Real-Time Dashboards: Monitor compliance across all locations in real-time, reducing the risk of costly quality issues.

- Drill-Down Analytics: Understand performance at both macro and micro levels, from corporate-wide trends to individual site performance.

- Regulatory Alignment: Ensure consistent compliance across jurisdictions, reducing the risk of fines and regulatory penalties.

For instance, a leading global food and beverage company leveraged AuditComply’s reporting tools to identify a performance gap between its best and worst-performing plants, prompting a targeted improvement plan.

Proven Scalability – Sysco’s Success Story

Sysco, the world’s largest broadline foodservice distributor, faced the challenge of managing Food Safety, Quality Assurance (FSQA), and supplier management across its vast network of distribution centers. By adopting AuditComply, Sysco significantly improved compliance visibility, streamlined processes, and reduced audit preparation time.

Sysco’s success demonstrates AuditComply’s ability to scale alongside its customers, supporting their growth while reducing operational costs and improving overall quality control.

Why AuditComply is the Right Choice for Multi-Site Manufacturers

AuditComply is engineered for scalability, providing manufacturers with a robust platform for managing complex, multi-site operations. With a focus on rapid implementation, flexible compliance structures, and powerful analytics, AuditComply transforms the way manufacturers manage quality and compliance at scale.

The Bottom Line:

For manufacturers looking to confidently scale their operations while maintaining the highest quality and compliance standards, AuditComply offers the tools, insights, and support needed to succeed in today’s competitive, multi-site manufacturing environment.

If you’re facing similar challenges and want to learn more about how AuditComply can transform your Risk, Quality, Compliance, and Supplier operations, reach out to us at: info@auditcomply.com.